Why Most Magento-to-BigCommerce Migrations Fail at the Inventory Layer

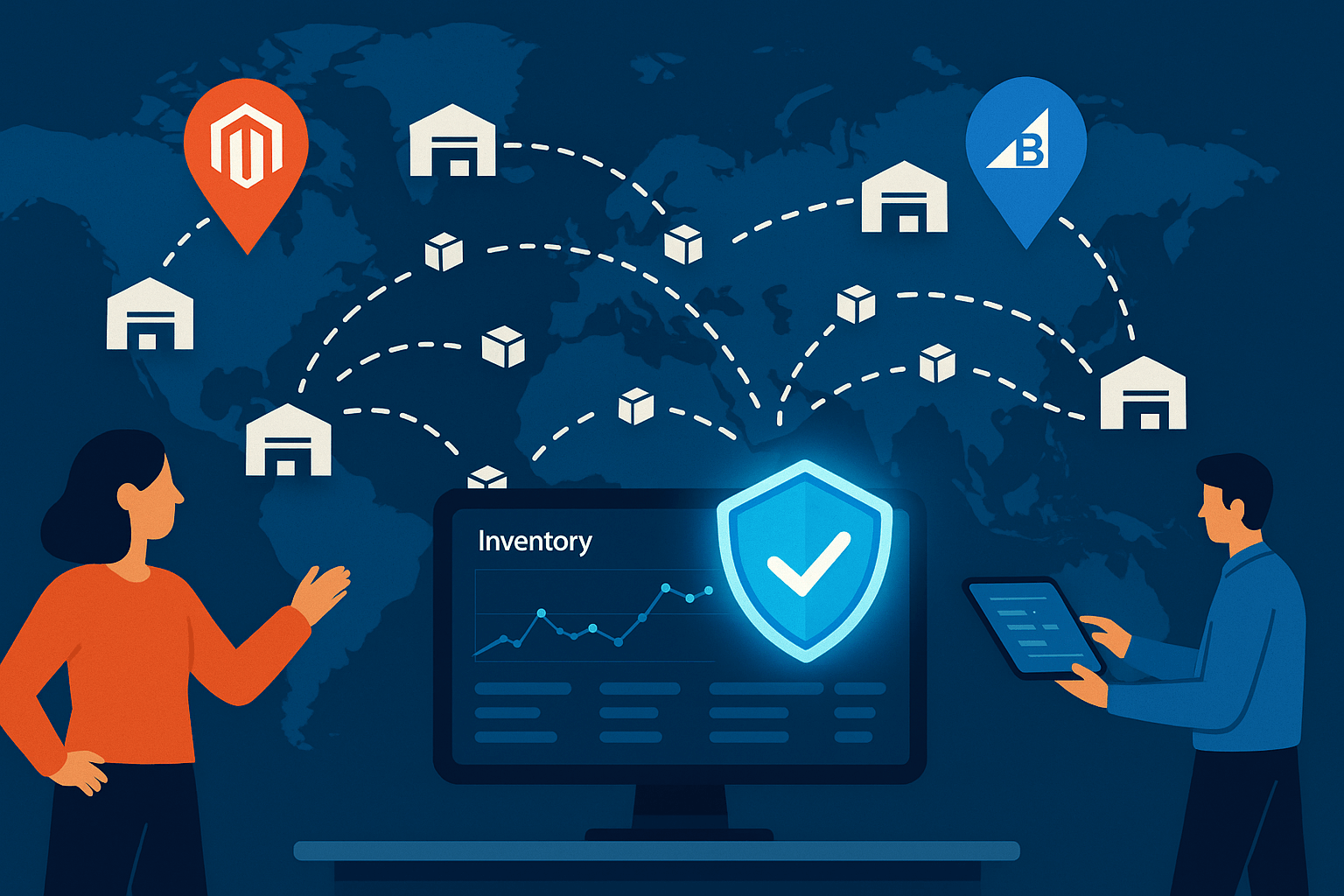

Most replatforming projects treat inventory like it’s just a number—a field to migrate, a data set to import. They don’t treat it like what it actually is: a dynamic system that drives every fulfillment decision, every customer promise, and every warehouse operation you run.

This is especially true when migrating from Magento to BigCommerce in a B2B environment. Magento, for all its chaos, gives technical teams deep control over how e-commerce inventory behaves—at the warehouse level, per product, per customer group, and even in coordination with ERP logic. You can build region-specific allocation, safety stock buffers, and dynamic stock rules that interact with other systems. That flexibility often comes at a cost, but for B2B distributors with multi-warehouse operations, it’s the only reason their fulfillment works.

Then comes the migration.

BigCommerce’s inventory model is simpler. It supports multiple locations out of the box but lacks the deep conditional logic many B2B operations depend on. You can set stock levels per location, sure. But how do you enforce warehouse prioritization? What if you have contractual inventory limits per customer group? What about tiered allocation across zones? Out of the box, BigCommerce doesn’t offer answers.

So during the migration, most teams—whether in-house, agency, or platform-provided—take the easiest path forward. They flatten the model. Instead of mapping warehouse logic, they consolidate stock into a single location. Or worse, they spread inventory across locations in the backend but don’t reflect that logic in the storefront or cart. The system looks functional, but the underlying behavior is broken.

And it doesn’t break during the demo. It breaks the first time a regional buyer places a bulk order for a top-mover SKU and the wrong warehouse ships it. It breaks when a location is out of stock, but the system doesn’t know it until after the cart clears. It breaks when your ERP sync shows a 3-day delay for restock, but the e-commerce front end still promises next-day delivery.

It’s what happens when complex behavior is dropped on a new platform without redesigning how it needs to function.

And the root cause is always the same: the inventory system wasn’t treated as a system. It was treated as data for migration. So the logic that made fulfillment work—the routing rules, warehouse priorities, and real-time syncing behaviors—never made the jump.

What Inventory Precision Actually Means When You Have More Than One Warehouse

Most people think “inventory accuracy” means the number in the backend matches the number on the shelf. That’s only part of it. If you run multiple warehouses and serve B2B customers, that number also has to reflect where the stock is, who it’s allocated to, whether it’s available to sell, and whether that availability should even be shown to the buyer.

In Magento, teams often build their own rules around this. Stock in WareWarehouse A may reserve its stock exclusively for West Coast customers.might handle B2B orders over a certain size. Some SKUs ship from a single location for compliance reasons. Others are reserved for certain accounts based on purchase volume or contract terms. These rules live in code, ERP sync logic, or even warehouse-level buffers. But they’re real. And they’re critical.

So when you move to BigCommerce, the question isn’t “does it support multiple inventory locations.” It does—technically. The question is, can it replicate the way your inventory system actually works?

Out of the box, BigCommerce treats inventory locations as data points—not rule sets. It can hold inventory counts per location, but it won’t prioritize fulfillment logic based on customer type or region. It won’t restrict visibility of certain stock to specific accounts. It doesn’t manage reservation logic for high-volume buyers. If you need that logic, you have to bring it with you. And you need to decide whether it lives in BigCommerce, in your ERP, or in a middleware layer that connects them.

And let’s be clear: this isn’t about “optimizing operations.” It’s about making sure the system doesn’t create errors. If a buyer adds 200 units to their cart, and those units are split across three locations, does the front end know? Does it tell the buyer that only one warehouse can meet the required lead time? Does it block the order if none can fulfill it in full?

Without that level of control, you’re not running a system—you’re running a gamble. The buyer sees what looks like clean stock. Your ops team sees fragmented inventory across facilities. Your warehouse team gets the wrong picklist. And your support team gets the email when delivery dates slip.

Inventory precision is not optional. In a multi-warehouse setup, it’s the one thing keeping promises made by your e-commerce platform from becoming problems for your operations team.

Why Magento and BigCommerce Don’t Speak the Same Inventory Language

Magento gives you control because it assumes you’ll need to customize everything. Inventory logic is included. Most mid-sized B2B teams that run Magento don’t use the default stock module—they’ve layered in third-party extensions, custom fulfillment rules, or direct integrations with ERPs and warehouse systems. Over time, that stack starts acting like a tailored inventory engine. It’s messy, but it works—because it matches how the business actually moves product.

BigCommerce is different. It assumes a simpler model from the start. Inventory exists. It lives at a “location.” You assign product availability by site. But there’s no logic layer that decides which location should fulfill a given order, no reservation system that blocks double-sells across channels, and no concept of fulfillment priority based on rules like customer tier or region. You can connect external systems to simulate that behavior, but BigCommerce doesn’t enforce it natively.

This is where most migrations go sideways. The team scopes the project around the catalog, the design, and the checkout. Inventory is treated like static data: export stock levels from Magento, import them into BigCommerce, and turn it on. No one pauses to ask: what happens to warehouse routing? What about the ERP sync that reserves inventory for top-tier clients? What about regional rules for HAZMAT SKUs or freight thresholds?

Those systems existed—but they weren’t documented. And if they’re not rebuilt explicitly, they vanish.

The platform doesn’t throw an error when this happens. Everything looks fine. Inventory shows up in the backend. Products are shoppable. Orders start flowing. But underneath, the logic is gone. Orders start routing unpredictably. Allocation rules don’t trigger. Stockouts appear in the wrong regions. The ERP starts logging exceptions that weren’t happening before.

And because inventory misfires are slow to surface, no one flags it right away. It takes a few cycles—a support spike, a missed SLA, a drop in fulfillment efficiency—before someone realizes the platform is acting differently.

That difference is almost never a bug. It’s just that the Magento logic was never ported—because BigCommerce didn’t have a place to receive it.

If the inventory system you had was built around behavior, not just data, then a direct migration won’t cut it. You have to translate how the logic worked, not just what the numbers were.

Mapping Inventory Around Business Needs, Not Just Warehouses

Before a single record gets migrated, you need to get clear on what your current inventory system is actually doing. This is where most teams start too late. They export SKUs and quantities, prep for import, and assume everything else can be figured out during QA. That’s how logic gets lost.

Start by mapping your warehouses. Not just their names, but their roles. Which ones fulfill e-commerce orders directly? Which serve as overflow? Which are staging points for bulk freight, and which handle only certain product lines? Some warehouses aren’t fulfillment centers at all—they’re inventory buffers that push stock downstream on schedule. Label those distinctions clearly. They affect routing, visibility, and order splitting.

Next, capture the rules that govern how those warehouses are used. For example, if two facilities hold the same SKU, is one the default? Do certain customer types pull from a specific region? Are high-value SKUs limited to a facility with extra security? Are some warehouses blocked from shipping to certain zones? This isn’t theory—these are decisions being made today, often invisibly, inside the Magento implementation or your ERP.

Then, document inventory statements. Available stock is only part of the story. What counts as “reserved”? Is that a real-time deduction, or does it happen at invoice? Do you support backorders—and if so, do different SKUs or customer types trigger different lead times? How are replenishment cycles tracked—per SKU, per warehouse, or in the ERP alone? BigCommerce won’t track this information for you unless you explicitly model it.

You’ll also need to track what’s currently automated. Which systems are syncing inventory to Magento now? What happens if a warehouse restocks in the ERP—does that update product visibility in real time, or only at fixed intervals? If you’re relying on middleware, does it filter data by warehouse status or sync everything regardless of location logic?

This is the layer of complexity that determines whether your BigCommerce implementation will behave like your Magento build—or simply display the same products while ignoring how they’re supposed to move.

Treat this like a system audit. You’re not just migrating inventory. You’re re-establishing how stock is defined, assigned, and used to make fulfillment decisions. Skip this step, and you’ll be rebuilding from production issues instead of clean specs.

Designing Your Inventory Software Stack Around Real Warehouse Logic

BigCommerce doesn’t come with your warehouse logic built in, and it won’t guess. If you want the platform to behave like your Magento stack did, you have to design the behavior yourself. The stock levels, location names, and SKU assignments are just the start. What matters is how they’re used.

Start with setting up inventory locations in BigCommerce that reflect your actual warehouse structure. That part’s straightforward, you can create as many locations as you need. But on their own, these locations don’t do anything. They don’t prioritize routing. They don’t apply rules based on geography or customer tier. That part’s up to you.

You’ll need a way to determine, at the moment of cart creation or checkout, which warehouse should fulfill an order based on customer address, SKU availability, and any business logic you’ve defined. BigCommerce can’t evaluate those conditions natively. So the logic has to live in one of three places: your ERP, a middleware layer (like a custom API service or iPaaS), or a custom front-end experience built on the Storefront API.

In most cases, middleware is where this logic ends up. It reads the cart or order payload, checks warehouse availability and rules, and assigns fulfillment before the order is finalized. If a product is stocked in multiple locations, it chooses the right one. If the default warehouse is out of stock, it can fall back to overflow rules. That decision is then written back into the order, often via a tag, custom field, or metafield, so downstream systems know how to fulfill it.

You’ll also need to make a call on where your inventory data comes from. BigCommerce allows manual entry, but that’s not viable for live operations. If your ERP or WMS is already the source of truth, continue to sync from there. But sync frequency matters. Inventory should update in near real-time, especially if you’re selling high-velocity SKUs across multiple warehouses. A delay of even 10–15 minutes can result in oversells or incorrect routing.

Many teams also forget to control what the front end shows. Just because inventory is available somewhere doesn’t mean every buyer should see it. If a West Coast buyer adds a product to the cart, and the only available stock is in New Jersey, that has cost and lead time implications. If you don’t surface that context, you’ll have downstream escalations that the system should have prevented.

This is where custom front-end logic matters. You can’t rely on the default “X in stock” label. You’ll need to write logic that evaluates the buyer’s shipping region, checks which warehouses can fulfill, and displays accurate availability per SKU, before checkout. This can be done via custom scripts or using BigCommerce’s APIs, but it has to be part of the build.

Finally, make sure fulfillment systems downstream can read the decisions made upstream. If the order is tagged with a warehouse ID or routing logic, your ERP and WMS need to recognize that tag and act on it. That handoff — from front-end logic to operational systems — is what makes the entire inventory architecture function. Without it, your design will look good in staging and break the first time an order spans two fulfillment rules.

You’re not designing for what BigCommerce supports. You’re designing for what your warehouse operation requires. If those two things aren’t matched explicitly, the migration will succeed on paper and fail in practice.

Executing the Migration Without Breaking Fulfillment

You’re not shutting down fulfillment just because you’re migrating platforms, but you also can’t afford inventory drift, split shipments, or misrouted orders. The key is to treat the transition like a system handoff, where logic, rules, and behavior are securely migrated, not just a bulk data push.

Start by freezing only what actually matters: product edits, warehouse mapping, and automated syncs between your ERP and Magento. This gives you room to prep BigCommerce to match how your fulfillment engine really works—not just where items are stored, but how they flow. That includes logic like buffer stock, allocation rules, and fallback locations.

Don’t migrate the entire catalog on day one. Start with your top-selling SKUs. It’s the fastest way to pressure-test stock accuracy by location, verify regional fulfillment logic, and run through real order flows before things go live.

While Magento is still active, BigCommerce should be receiving the same inventory updates. This live sync lets you catch mismatches early, before you flip the switch.

When it’s time to cut over, pick a low-volume window. Point the domain to BigCommerce, pause Magento orders, and confirm BigCommerce is routing new orders properly, including warehouse tags and downstream logic.

Track in-flight orders closely, everything that’s been paid for but not yet shipped. This is where duplicate fulfillment and phantom stock issues usually show up. Post-launch, monitor for edge cases: surprise backorders, misrouted orders, and fulfillment from the wrong warehouse. These aren’t bugs—they’re signals that part of the logic didn’t make it over.

The goal isn’t to replicate the old setup perfectly. It’s to make sure the outcomes—inventory behavior, reservation logic, fulfillment flow, work exactly as expected. If it feels like nothing changed on the ops side, that’s how you know the migration actually worked.

What Operational Excellence Looks Like Post-Migration

If your inventory logic makes it through the migration intact, the benefits show up immediately, not just in the data, but in how your teams work.

Fulfillment becomes more predictable. Orders route to the correct warehouse on the first try. Stock reservations hold where they’re supposed to. Lead times shown on the site match what ops can deliver.

Sales and support stop chasing inventory questions. They can see what’s available, by warehouse, in real time, without asking IT. Warehouse teams stop second-guessing pick tickets because the routing logic already respects site constraints and region coverage.

Inventory turns improve. You’re not sitting on overstock in one location while another goes dry. You can move SKUs strategically instead of reacting to backorders.

And buyers get what they were promised. No surprise delays, no partial shipments unless allowed by rule, and no “we’ll check with the warehouse” follow-ups. The system reflects what’s actually possible and follows through.

That’s the difference between a functional store and a reliable operation.

What Not to Skip — Pitfalls That Break at Scale

Ignoring Replenishment Logic

Your ERP might know when new stock is arriving — but if BigCommerce doesn’t, the site has no way to show buyers what’s coming. Products look out of stock even if inventory is inbound. Or worse, the store shows items as available with no lead time logic behind it. That gap creates order failures and lost sales.

Mishandling Split Shipments

BigCommerce can’t decide how to split orders on its own. If a product is stocked in multiple warehouses, and a buyer orders more than one location can fulfill, the logic needs to define: allow partials, delay full shipment, or block the order. Without clear rules, fulfillment gets delayed or split in ways that create extra freight costs — or confusion.

Assuming Platform Defaults Match Business Rules

Magento likely had hard-coded inventory logic tied to customer groups, regions, or contract types. BigCommerce doesn’t bring that over. If your team skips the step of rebuilding those rules or assumes “multiple locations” covers it, you’ll lose enforcement. The platform will treat all stock equally, even when your ops team can’t.

Hiding Real Inventory from the Buyer

If your product detail pages and cart experience don’t reflect what’s really available, at the warehouse level, for that buyer’s location, you’re inviting mismatches. Orders come in for items that can’t be fulfilled on time, or in full, or from the correct warehouse. And support ends up cleaning it up.

If you don’t model these things upfront, they’ll show up anyway in order exceptions, delivery delays, and internal escalations. The difference is whether they happen during QA or during your busiest sales week.

When to Bring in a Team That’s Done This Before

If your Magento setup includes custom warehouse logic, ERP-tied inventory buffers, or customer-specific allocation rules, this isn’t a project for a generic replatforming partner.

Most BigCommerce builds are run by teams who focus on theming, checkout UX, and frontend polish. They’ll migrate your products, rebuild your templates, and get you live — but they won’t ask how your warehouses prioritize fulfillment. They won’t rebuild the inventory reservation system that protected your B2B stock. And they won’t notice when your ERP integration silently drops the logic that kept multi-location orders aligned.

A good migration isn’t just about accuracy, it’s about continuity. The logic that supports inventory must be reimplemented with full awareness of how your systems actually behave. That means syncing the right fields, designing middleware that makes decisions, and surfacing availability logic in the right place, often before checkout.

It also means knowing how to test for the right failures. Not “does the SKU show up,” but “does the inventory update when a backorder clears?” “Does the warehouse routing still protect our contract clients?” “Do the split rules fire properly when stock is uneven across locations?”

If your team has never modeled this logic in BigCommerce before, you’re going to spend time and money rebuilding things that should have worked from day one. Or worse — you won’t realize what’s broken until support tickets start piling up.

A specialist team doesn’t just execute. They document the business rules you’ve been running for years and rebuild them where the new system expects them — even if that means creating logic that didn’t exist out of the box.

That’s the difference between a storefront relaunch and a real migration.

Critical Inventory Migration Checks for Magento to BigCommerce

Think of this as your pre-flight checklist and mapping table for making sure your new BigCommerce setup doesn’t lose the logic that’s been quietly keeping your operations running smoothly in Magento.

Warehouse Role Mapping Table

Use this table to document how each warehouse is actually used. This will drive fulfillment rules in BigCommerce or middleware.

| Warehouse Name | Fulfillment Role | Serves Which Customers? | Notes or Rules |

| WH-A | Primary eCom fulfillment | West Coast DTC + B2B Tier 1 | Priority shipping; holds buffer stock |

| WH-B | Overflow / backup | National | Kicks in if WH-A is under stock threshold |

| WH-C | Contract fulfillment only | B2B contract clients | Not exposed in storefront; reserved-only inventory |

Only include warehouses that affect eCommerce fulfillment — skip DCs or transfer hubs unless they impact stock visibility or routing.

Essential Migration Checklist

Use this checklist to confirm your new BigCommerce environment behaves like your Magento stack — especially around warehouse logic.

Warehouse Setup

☐ All active fulfillment locations are configured in BigCommerce

☐ Each location is tagged with metadata or rules for routing decisions

☐ Non-shipping warehouses (buffers, staging) are hidden from storefront

Inventory Sync

☐ Inventory updates flow from ERP/WMS into BigCommerce in near-real time

☐ Reservation logic (e.g. cart hold, VIP allocation) is preserved or rebuilt

☐ Inbound inventory logic (e.g. backorder visibility, lead time messaging) is modeled

Order Routing & Display

☐ Rules for assigning orders to warehouses are defined and tested (middleware or ERP)

☐ Buyers only see inventory that is available to them (by location, tier, or region)

☐ Split order logic is defined (block, delay, or partials) and reflected in the cart/checkout

Testing & Monitoring

☐ In-flight order tracking and cutover plan is in place.

☐ All top SKUs have been run through simulated order paths across locations.

☐ Tagging/fields for warehouse assignment are visible in orders and readable downstream.

Visibility Warning Signals (Post-Launch)

If you see any of these after migration, it likely means your warehouse logic didn’t come over cleanly:

- Orders routing to the wrong facility

- ERP stock shows available, but BigCommerce shows “out of stock”

- Buyers see or order from warehouses they shouldn’t

- Partial orders where the platform promised full fulfillment

- High-ticket items disappearing from cart due to stock mismatch

Build a BigCommerce Store That Won’t Break Under Real Orders

Most Magento-to-BigCommerce migrations get scoped around catalog, design, and payment flow. But if you run multiple warehouses, and inventory actually drives your business, none of that matters if fulfillment logic doesn’t survive the cut.

You don’t need a redesign. You need a migration plan that treats inventory like infrastructure: mapped, tested, and rebuilt for how your operation actually works.

That’s what we do.

At Optimum7, we’ve rebuilt location-specific inventory logic, ERP-integrated stock sync, and custom routing workflows for B2B distributors moving off Magento, without breaking fulfillment. We don’t push defaults. We don’t assume logic will “just work.” We model your system from the ground up, and we make sure it behaves correctly from day one.

If you’re migrating to BigCommerce and can’t afford surprises in your warehouse, we should talk.

Contact us to scope your migration the right way, and keep inventory from becoming your most expensive blind spot.