Why Repairs Fall Apart Over a Missing Part

It usually starts small. A field technician opens a shipment on-site—crates, boxes, everything neatly packed. The replacement assembly is there, heavy and precise. The job should be straightforward. But as the technician starts the repair, something is missing. A gasket. A set of bolts. A seal worth five dollars.

Suddenly, the entire repair grinds to a halt. The crew can’t finish the job. The equipment stays offline, costing thousands of dollars an hour in lost production. The technician calls procurement, who calls the supplier. Overnight freight is arranged, customer service fields a heated complaint, and what should have been a clean, profitable order turns into a scramble to patch a mistake that never should have happened.

The truth is, the buyer didn’t forget. They ordered what they thought they needed. The problem was the portal. Shopify, as a powerful ecommerce platform, doesn’t know that a certain coupling needs a specific gasket. It doesn’t know that a pump replacement usually requires fresh seals and fasteners. Standard upsell apps try to cover the gap with generic prompts — “customers also bought this” — but in industrial ecommerce, those prompts aren’t just irrelevant. They’re dangerous.

In industrial repairs, missing a part is a failure. It creates downtime, erodes trust, and forces procurement teams to second-guess every order. And that’s why suppliers running on Shopify Plus need more than upsells. They need logic. Logic that knows which parts belong together, which consumables fail after 500 hours, and which fasteners are non-negotiable for a safe repair.

Because when the storefront enforces completeness, the buyer doesn’t just get a cart full of SKUs, they get a working solution. And that’s what keeps operations running, contracts safe, and relationships strong.

The Reality of Industrial Parts Buying

Buying industrial parts isn’t like adding a shirt and pair of shoes to a cart. It’s messy and technical, and the stakes are high enough that one wrong click can stop an entire operation.

Most orders start with pressure. A technician in the field sends word that a pump has failed or a gearbox is out of commission. A procurement officer jumps into the supplier’s portal, trying to build the order that will get equipment back online. The problem? They’re staring at an ecommerce catalog that could hold a million products, each one nearly indistinguishable unless you know the assembly by heart.

So they guess. They add the main assembly. They think they’ve got the right fasteners. They assume the existing seals will hold up for one more cycle. They check out, hoping they didn’t miss anything.

But that’s the problem, hope isn’t a process.

When the shipment arrives, technicians open the box and immediately see what’s missing. The part that seemed optional wasn’t. The gasket that looked standard wasn’t. The repair stalls, and the cycle of calls, rush orders, and frustration begins again.

This isn’t about incompetence. Buyers are smart. Technicians are experienced. The issue is that the system doesn’t help them. The portal shows them products, not solutions. It leaves the burden of knowing every dependency, every wear part, and every compatibility rule on the buyer. And when people are rushing to get production back online, those details slip through.

That’s the daily reality: procurement teams piecing together critical orders under pressure, with a system that forces them to guess instead of guiding them. And every time it happens, confidence in the supplier drops just a little more.

Why Standard Shopify Upsells Don’t Work in B2B

Shopify was built for consumer selling first. That’s why its upsell apps look the way they do — bright boxes at checkout suggesting, “You might also like…” or “Other customers bought this.”

In B2C, that’s fine. Someone buying shoes might actually want socks. A coffee buyer might toss a mug into the cart. But for an industrial buyer, those prompts feel almost insulting. When you’re ordering a replacement pump for a production line that’s bleeding thousands of dollars an hour, you don’t need “similar items.” You need the exact seal, fastener, and gasket that keep that pump running.

Generic upsells don’t just fail; they add noise at the worst possible moment. Instead of confidence, they create doubt. A buyer sees irrelevant recommendations and starts wondering: “Did I choose the wrong product? Did I miss something important? Why is this system showing me random parts instead of what I actually need?”

And here’s the painful truth: B2B buyers don’t care about being sold more. They care about being sold right. Suggesting an unrelated accessory undermines trust. It tells the buyer that the system doesn’t understand their job, their repair, or the urgency of what they’re doing.

That’s why standard upsells fail in B2B. They treat critical repairs like casual shopping trips. And when even one required component is missing, the supplier pays the price in support calls, rush shipping, and strained relationships.

Industrial e-commerce doesn’t need “nice-to-have” upsells. It needs a system that safeguards completeness. That difference — between selling more and selling right — is where Shopify Plus has to evolve for manufacturers and suppliers.

The Business Impact of Incomplete Orders

Every incomplete order creates a ripple effect that goes far beyond a single missing SKU.

First, there’s the cost of re-shipping. A warehouse team has to pick and pack again. Logistics has to book another truck or air freight. The supplier eats the cost of shipping twice on an order that may not even carry high margins to begin with. If the customer insists on overnight delivery the hit is even harder.

Then there’s the cost of time. A technician in the field, already under pressure, can’t finish the repair. Equipment sits idle, and production schedules slip. In industries like manufacturing, energy, or transportation, a day of downtime can translate into tens of thousands of dollars lost. And in the customer’s eyes, that loss traces straight back to the supplier who shipped an incomplete order.

Customer service gets pulled in next. And unlike retail, where a brand can absorb a mistake across multiple sales channels, in industrial B2B, one incomplete order can trigger angry calls, rush freight, and stalled production. Reps who should be helping grow accounts spend their time apologizing, issuing credits, and trying to smooth over mistakes that the system should have prevented.

But the deepest cost is trust. Procurement officers don’t forget when an order fails. They remember the frustration in the field, the rush charges, and the late-night calls. Even if the parts eventually arrive, the relationship has taken a hit. The next time a contract is up for renewal, that memory weighs heavy.

Incomplete orders are more than inefficiency. They’re a breach of reliability. And in B2B a reputation for missed parts can quietly erode millions in repeat revenue.

What “Right-Part Recommendations” Look Like in Shopify Plus

Imagine a buyer adding a replacement pump to their cart. In a standard Shopify store, that’s where it ends: one SKU, one item in the cart. But in a Shopify Plus portal extended with industrial logic, something different happens.

The system recognizes the pump isn’t a standalone product. It knows the pump can’t be installed without a specific gasket set, mounting bolts, and a seal that should always be replaced during installation. So as soon as the pump is added, the storefront surfaces those items with a message that feels less like a sales pitch and more like a checklist:

“For this repair, you’ll also need…”

The buyer isn’t asked to guess. They aren’t left to hope they remembered every component. The portal enforces completeness by surfacing the required SKUs right there in the flow.

And this isn’t a random upsell carousel. It’s context-driven. A gasket for this pump isn’t the same as a gasket for the older model, and the system knows the difference. Recommendations are tied to assemblies, service manuals, and replacement cycles, not to vague purchase history.

For the buyer, this feels like working with a knowledgeable parts counter rep, the one who always says, “Don’t forget the O-rings, you’ll need a fresh set.” Except now that guidance happens online, instantly, at the point of purchase.

This is what “right-part recommendations” look like inside Shopify Plus. Not noise, not clutter, not upsells for the sake of higher cart totals. Instead, it’s about safeguarding the repair itself, making sure every shipment leaves complete, accurate, and ready to install.

Using API Integrations to Map Repair Logic in Shopify Plus

The hardest part of making recommendations useful isn’t the coding. It’s the thinking. It’s mapping out the logic that already lives in your service manuals and in the heads of your experienced sales engineers.

Every assembly has dependencies. A gearbox isn’t just a gearbox—it’s seals, bearings, and fasteners that always need replacing when the housing comes off. A pump isn’t just an SKU; it’s the gaskets and couplings that keep it functional in the field. That knowledge exists, but it’s usually scattered across paper manuals, tribal memory, and unstructured customer data from years of support calls.

Bringing that logic into Shopify Plus means structuring it in a way the storefront can use. That might look like:

- Adding compatibility rules into product metafields (e.g., Pump Model 300 → Seal Kit 42).

- Tagging wear parts with usage cycles (e.g., replace every 500 hours).

- Linking assemblies to the kits and subcomponents they depend on.

It doesn’t need to be perfect from day one. Most manufacturers find that 80% of their orders involve the same assemblies and the same failure points. Start there. Map the relationships for your most common repair jobs, then expand outward as the system proves itself.

When it’s done right, the storefront begins to feel less like a catalog and more like a digital service manual. A buyer selecting a part isn’t just given an SKU; they’re walked through the logic of the repair. The system remembers what seasoned reps already know and puts it where it belongs, right in front of the customer, before the order leaves incomplete.

The payoff is immediate. Fewer follow-up shipments. Fewer late-night support calls. More orders that arrive complete, the first time. And a growing sense among buyers that your portal “just gets it.”

Checkout and Reorder Safeguards

Even when buyers think they’ve got everything, mistakes slip through at checkout. Stress, deadlines, and giant catalogs don’t mix well, and that’s where logic-driven safeguards step in.

Picture this:a procurement officer builds a cart for a gearbox repair. They’ve added the housing, the bearings, and the shaft. At checkout, the system runs a quiet check in the background. It recognizes the gasket kit isn’t in the cart, and without it, the repair won’t hold. Instead of letting the order go through incomplete, with custom checkout validation, the portal can stop and prompt:

“This order is missing the required gasket kit. Would you like to add it before checkout?”

It’s not an upsell. It’s a safety net. The buyer breathes easier, clicks “add,” and finishes the order knowing they won’t be blindsided later.

Reorders work the same way. A technician might reorder a pump they’ve bought before, but when connected to ERP data or custom tagging, the system can remind buyers that seals are due for replacement. When the pump is added to the cart, the portal nudges: “Seals for this assembly are recommended for replacement every 500 hours. Add now to avoid a second shipment.”

These safeguards shift the relationship. The supplier is no longer just moving boxes, they’re anticipating needs. They’re protecting the buyer from the kind of mistakes that cost time, money, and credibility in the field.

For the buyer, that kind of reliability turns every order into a confidence-building exercise. For the supplier, it eliminates the endless cycle of emergency shipments and late-night phone calls that eat away at margins.

It’s not about selling more. It’s about ensuring no order leaves half-done.

Benefits for Buyers: Less Stress, More Confidence

For buyers, ordering industrial parts is stressful. There’s always that nagging question: “Did I miss something?” Because if they did, the consequences would be costly.

An engineer placing an order wants to know that when the box arrives, the repair can be finished. No scrambling for missing bolts. No overnight freight for a five-dollar seal. No awkward calls to their manager explaining why the line is still down. A system that enforces completeness takes that weight off their shoulders.

Procurement officers feel it too. Their job is already a balancing act between budgets, timelines, and endless approvals. The last thing they want is a technician calling to say the repair stalled because the order was incomplete. When the portal itself double-checks the logic and fills in the gaps, procurement officers gain confidence. They can place orders knowing the system has their back.

Even technicians in the field feel the difference. Instead of ripping open a crate only to discover what’s missing, they get everything they need in one shipment. Repairs get done on time, projects stay on schedule, and trust builds — not just in the supplier, but in the people who placed the order.

For buyers at every level, it’s less stress and more certainty. And that certainty becomes a reason to come back. Because when your system consistently delivers complete solutions instead of half-finished shipments, it’s not just easier to buy from you — it’s riskier to buy from anyone else.

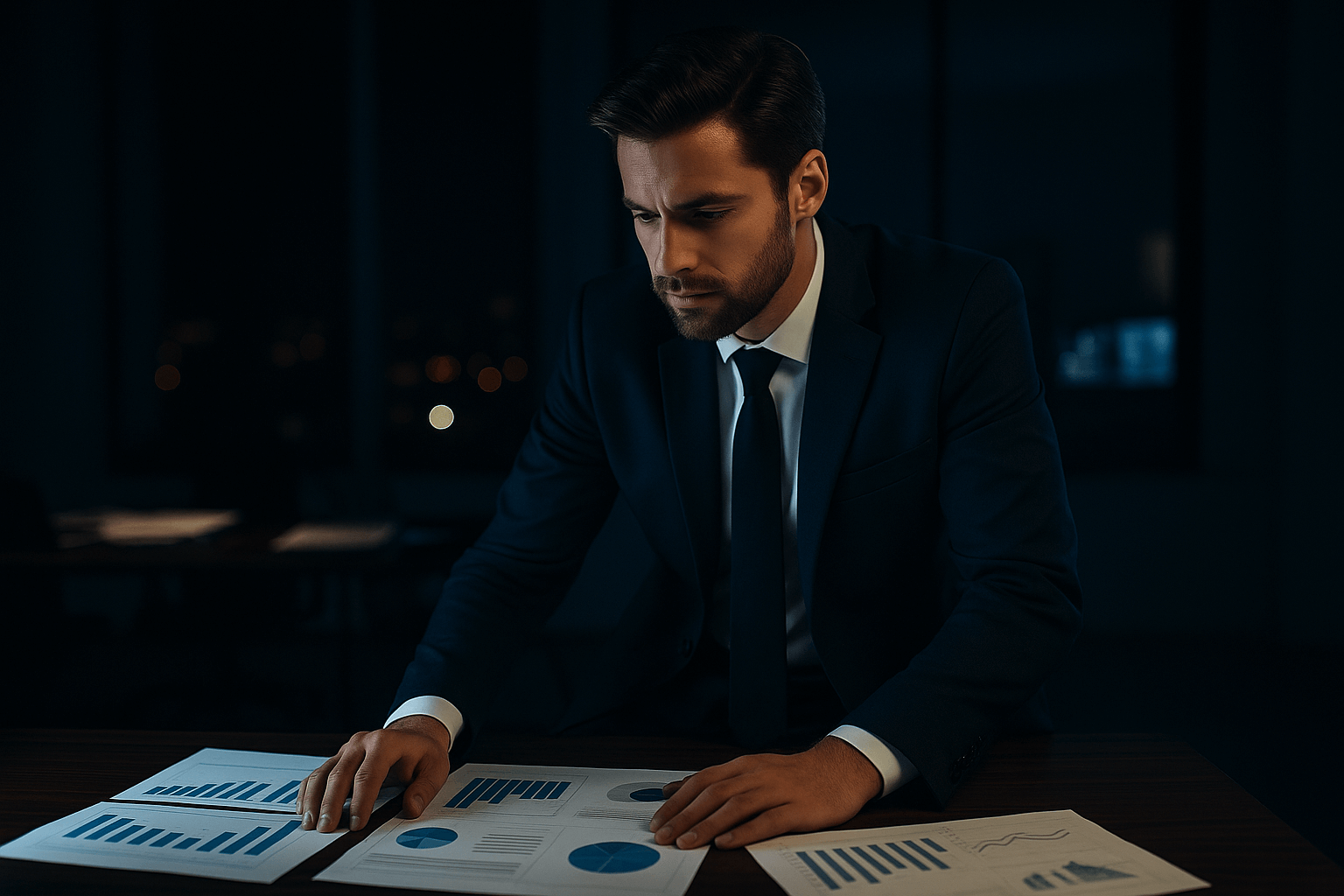

Benefits for Suppliers: Fewer Calls, Lower Costs, Stronger Trust

Every incomplete order that leaves your warehouse comes back to you twice—once as a complaint and again as a cost. That’s what “right-part recommendations” eliminate.

For customer service, it means fewer angry phone calls. Instead of technicians demanding rush shipments or procurement officers chasing missing parts, support teams can focus on building relationships that actually drive account growth. They stop being firefighters and start being trusted advisors.

For operations, it means efficiency. Every re-shipment requires picking, packing, labeling, and freight. That work isn’t free—it burns labor, eats into margins, throws off logistics schedules, and drags down overall efficiency across the operation. When orders go out complete the first time, warehouses run smoother, freight costs shrink, and profit margins actually hold.

For sales, it means reputation. Reps hate apologizing for things they didn’t cause. They hate explaining to buyers why a gasket wasn’t included or why another shipment is needed. When the system enforces completeness, reps stop losing credibility over mistakes that should never have happened. Instead, they’re remembered as the partner whose portal “just works.”

And at the leadership level, the benefit is strategic. Fewer errors mean happier accounts. Happier accounts renew contracts, grow spending, and open doors to new customers through internal referrals. The supplier who consistently gets orders right becomes the safe choice—the one procurement champions when it’s time to decide who wins the next contract.

In other words, complete orders don’t just save you from costs. They create the kind of reliability that industrial buyers reward with loyalty.

Overcoming Challenges in Building Recommendation Logic

Every supplier who hears about mapping repair logic into Shopify has the same reaction: “That sounds like a nightmare with our catalog.” And it’s a fair reaction. Most industrial catalogs aren’t tidy; they’re sprawling, messy, and loaded with decades of product variations. But the truth is, you don’t have to solve everything at once to make a difference.

The first hurdle is the size of the catalog. Thousands of SKUs, multiple generations of assemblies — it feels impossible. The way through is to start small. Look at the ten or twenty assemblies that drive most of your repeat calls or re-shipments. The ones that keep coming up in complaints: “We forgot the gaskets again.” Fix those first. Once you see the lift — fewer support calls, fewer rush shipments — you’ll know it’s worth expanding.

The second fear is cluttering the buyer’s cart. No one wants a checkout page that looks like a parts explosion diagram. But this isn’t about dumping every possible add-on in front of the customer. It’s about surfacing the handful of items that make or break the repair. Presented clearly — “required for installation” or “due for replacement at this cycle” — buyers see them as guardrails, not noise.

And then there’s the data problem. Most of the logic you need isn’t neatly stored in Shopify. It lives in service manuals, in spreadsheets, or in the heads of sales engineers who have been answering the same questions for twenty years. That feels daunting until you realize: the knowledge already exists. It’s just a matter of pulling it out of the shadows and making it part of the storefront. Start with conversations, not code.

The truth is, these challenges feel big because they’ve been ignored for so long. But the cost of not solving them is bigger. Every day without repair logic mapped is another day of incomplete orders, angry calls, and wasted freight. Building it isn’t about perfection. It’s about progress — one assembly at a time, until your store stops being a guessing game and starts being the tool buyers actually trust.

Turning Your Online Store Into a Competitive Advantage

In B2B, buyers don’t reward suppliers for being “good enough.” They reward the ones who make their lives easier. And nothing builds loyalty faster than a system that quietly makes sure a repair never stalls over a forgotten part.

Think about how engineers and procurement officers talk internally. They don’t sit around praising a slick-looking storefront. They talk about who delivered on time. Who kept their project moving. Who saved them from embarrassment when the field tech opened the crate and had everything they needed, down to the last bolt. That’s the supplier they recommend at the next meeting. That’s the supplier procurement pushes to renew with.

When you implement logic-driven recommendations, you set yourself apart. While competitors are still running on generic upsell apps—tossing irrelevant products into the cart like it’s a consumer store—your portal becomes the one that acts like a repair partner. You’re not trying to sell extra SKUs; you’re making sure the buyer doesn’t fail in the field.

And here’s the real shift: once buyers experience that, they won’t go back. The supplier who nails this first sets the standard. Everyone else looks careless by comparison. Generic upsells feel sloppy. Missing parts feel inexcusable. The bar moves higher, and the ones who led the change get remembered as the safe bet.

In industrial sales, that reputation is worth more than price cuts or promotions. Reliability is currency. And the suppliers who invest in it now will lock in accounts before competitors even realize what changed.

How to Enforce Complete Repair Orders in Your Shopify Account

This isn’t about “selling more.” It’s about protecting your customers from failure in the field. Walk through this toolkit with your ecommerce and operations team. If you can’t check these off, you’re leaving buyers exposed to incomplete shipments — and exposing yourself to costly calls, rush freight, and lost trust.

Map the Repair Logic You Already Know

Don’t start with code — start with tribal knowledge.

| Task | Why It Matters | Status |

| Identify top 10 assemblies that drive most service calls | 80% of errors come from the same common repairs | ☐ |

| Document required consumables for each assembly (gaskets, seals, bolts) | Buyers shouldn’t have to guess what’s non-negotiable | ☐ |

| Translate service manuals and sales engineer notes into simple rules | This knowledge already exists, but it’s scattered | ☐ |

Run a “repair completeness workshop” with service engineers and reps. Capture their common phrases like “don’t forget the O-rings” — that’s your recommendation logic.

Embed Recommendations Into Shopify Plus

Turn repair logic into guidance your portal enforces.

| Action | Example | Status |

| Use metafields to link assemblies to required kits | Pump Model 300 → Seal Kit 42 | ☐ |

| Add wear-cycle logic (replace every 500 hours) | Seals prompt automatically on repeat orders | ☐ |

| Build clear, contextual prompts | “This order is missing the gasket kit required for installation.” | ☐ |

Avoid “customers also bought.” Instead, phrase prompts as safety nets: “Required for installation” or “Due for replacement.”

Safeguard Checkout and Reorders

Catch mistakes before they leave the warehouse.

| Checkpoint | Why It Matters | Status |

| Pre-checkout validation for missing dependencies | Stops incomplete orders at the last moment | ☐ |

| Reorder prompts tied to service cycles | Ensures recurring consumables don’t slip through | ☐ |

| Store recommendations in account history | Gives procurement teams a complete trail of what’s needed | ☐ |

Position this as protection, not a sales tactic. Buyers feel relief, not pressure.

Track ROI in Trust, Not Just Dollars

Measure the impact where it really shows up.

| Metric | Target | Notes |

| Repeat support calls about missing parts | ↓ 50–70% | |

| Rush shipments per quarter | ↓ 40% | |

| Customer trust feedback | Procurement officers saying “your portal just works” | |

| Contract renewal confidence | Buyers citing reliability as a reason to stay |

The first sign of success is silence — fewer frantic calls asking, “Did we forget something?”

Generic upsells sell noise. Right-part recommendations sell trust. When every repair order leaves complete, your buyers stop second-guessing and start relying on your portal as if it were their best technician.

From Upsell to Assurance

In industrial ecommerce, missing a part isn’t a missed sales opportunity — it’s a broken repair. It means a line stays down, a technician gets stuck, and a supplier takes the blame. That’s why treating critical repairs with consumer-style upsells is a losing game.

What buyers need isn’t a push for higher online sales. They need assurance that when they hit checkout, every part required for the job will arrive in one shipment, ready to install. And when your Shopify Plus portal enforces that logic, you stop being just another parts supplier. You become the partner buyers trust to keep their operations running.

The suppliers who make this shift will stand out fast. They’ll cut support calls in half, protect margins by eliminating repeat shipments, and win loyalty in the only way that matters in B2B: by removing risk for the customer. Everyone else will still be explaining why the gasket or fasteners didn’t make it into the box.

If you want to go for the next step, contact us. We’ll show you how to map the hidden knowledge in your catalog into Shopify Plus so every order is complete, every shipment is right, and every customer trusts your portal to deliver more than parts—it delivers confidence.